HARROW DISC BLADES

Disc Blade, Notched/Cutway Disc Blade, Plain/Smooth Disk Blade, Disc Harrow Blade, Agriculture Harrow Disc Blades, Agriculture Disc, Farm Machinery Part-Harrow Discs.

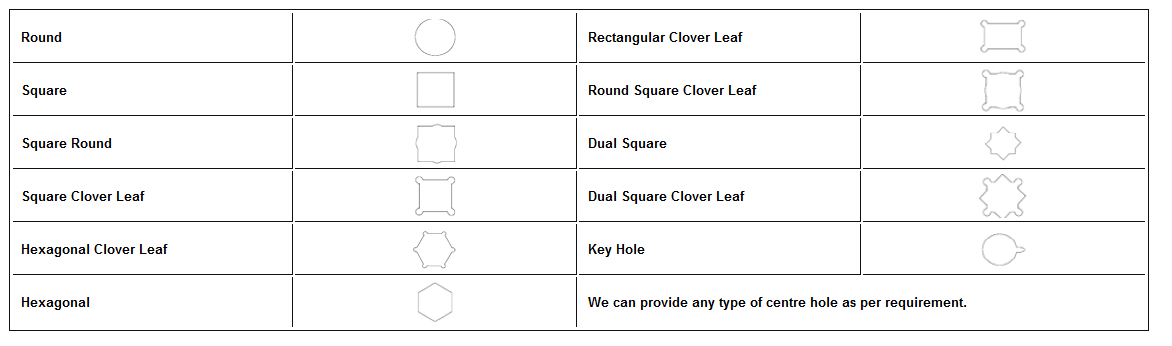

Currently we are manufacturing and exporting harrow and plough discs in High Carbon Steel and Boron Steel with scores of sizes ranging from 12 inches to 30 inches in diameter and 3 mm to 14mm in thickness. To manufacture Harrow disc we use High Carbon Steel EN 45 i.e. equivalent to SAE 1070 grade and Boron Steel EN 10083 (30 MN B5) grade material. We maintain hardness of the Harrow disc from 38 to 42 HRC in Carbon Steel and 48 to 52 HRC in boron steel. We manufacture Harrow disc with different type of center hole like - square, round, hex, Octave or as per the drawing and specification of the buyers. The varieties of Harrow disc blades that we manufacture are as below -

Our motto is customer satisfaction, consistency in quality, timely delivery and graded material at most competitive prices. Our production capacity endeavors us to serve domestic and export demand, enabling us to emerge as one of the major player in disc blade industry.

We believes that quality is the touchstone of success. For us, customer satisfaction and success are inextricably linked in any business. Inspired by such an attitude, we follow a well defined quality control policy as per which all the disc blades manufactured are closely inspected and passed through various quality control tests especially hardness. The tests such as dimensional and performance tests ensure flawless quality of the finished products. Then, the products are packed with utmost care which prevents them from getting rusted.

TYPES HARROW DISC BLADES

SMOOTH DISC BLADE

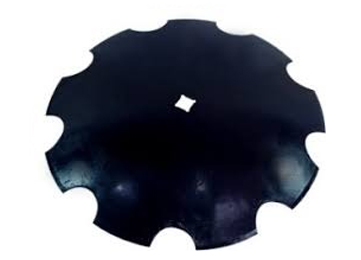

NOTCHED DISC

CONCAVE DISC

LEMKEN DISC BLADE

FLUTED DISC

CENTER LESS DISC

FLAT CENTER DISC

FLUTED COULTER DISC

CENTER LESS DISC

FLAT / COULTER DISC

WAVY COULTER DISC