QUALITY CONTROL AND PROCESS

CHEMICAL COMPOSITION TESTING

Raw material plays the most vital role in achieving the desired mechanical properties. We, at J.M.D Agro, inspect samples from raw material before taking it for production. Our team of Dedicated lab Technicians keep a close check on the composition of different steel grades.

HARDNESS TESTING

It measurers whether the hardness achieved is within the prescribed range or not. Different grades of steel give different hardness levels. It signifies the strength and toughness of the disc.

|

Material Chemical Compostion |

|||

| Description | Boron Steel | Carbon Steel | Chrome Steel |

| HRC | 47-52 | 38-42 | 40-44 |

| C | 0.3 | 0.65-0.75 | 0.74 |

| MN | 1.3 | 0.7 | 0.72 |

| S | 0.022 | 0.018 | 0.008 |

| P | 0.018 | 0.022 | 0.024 |

| Sl | 0.3 | 0.022 | 0.175 |

| CR | 0.27 | 0.024 | 0.255 |

| AL | 0.032 | 0.025 | X |

| B | 0.0027 | X | X |

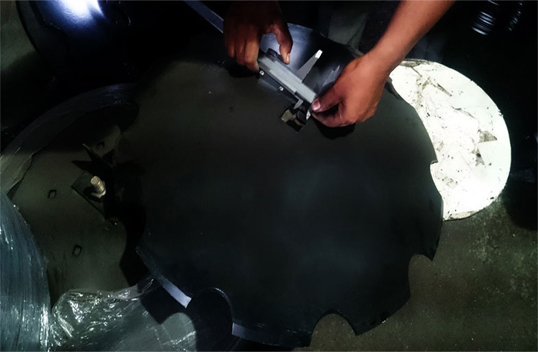

ECCENTRICITY TEST

This is done to make sure that there is no axial deviation of points on disc edge in a plain, parallel to the axis of the disc when the disc is rotated about its center.

BASIC DIMENSIONAL TEST INCLUDES

A. Normal Size | B. Thickness | C. Centre Hole | D. Concavity | E. Fixing Hole | F. PCD | G. Bevel Length | H. Bevel Angle

CRACK TEST AND VISUAL TESTING

The test helps to identify the location of any flaws such as surface cracks, scales, pits, nicks and burns etc. on this disc.

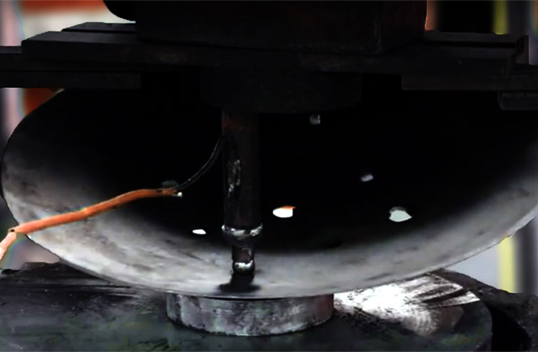

BALL TEST

Ball test is an essay applied to the raw material to make sure they have been cross-rolled, which is an imperative requirement for the fabrication of plowing discs. The test consists of applying load to a 1"(25,4 mm) ball, causing it to go through a pre-drilled hole of 1/2'' (12,7 mm) in the material. As a result, any cracks should not exceed a diameter of 3" (76,2mm).

CROSS ROLLING PROCESS

Disc blades made out of Cross-rolled sheets are stronger, tougher and have much lesser wear and tear. Cross rolling ensures optimum mixing of grains in the raw material, thus imparting suitable properties.

CUTTING PROCESS

This is the process in which sheet is cutted round in a shape of disc diameter required.

BENDING PROCESS

This is a process in which the round sheet is banded to form a disc in different die & different sizes.

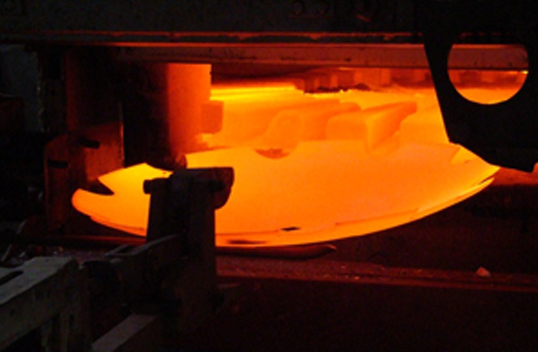

HEAT TREATMENT PROCESS

This is the process in which disc go for the heat treatment and quenching process to maintain the hardness of the Disc as per the Steel Raw Material.

SHOT BLASTING

Shot blasting of the disc blades increases the fatigue life of the disc blade. Due to automatic shot blasting, high quality surface finish disc blades are manufactured.

PACKING

Pack the disc in 50 & 100 Pcs. of bundles as per the disc size and weight, and wrap with Plastic sheet.